She gives me a call on Friday and we find some room in the middle and we work it out. So Saturday is moving day. There is this building, poles, shafts and wheels in another, and seat cushions in another. So we dig it all out and start to load up.

I have a 36’ gooseneck trailer so it’s pretty good sized but it still fills up fast. After about an hour of pulling, dragging, hauling and stuffing I have it in the trailer.

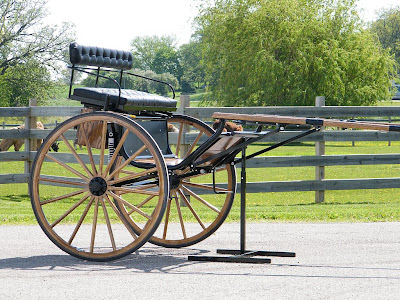

There is an extension top surrey, two runabouts, a Portland cutter, a running gear and a bunch of other poles, shafts and odds and ends.

If you have ever wondered what 30 years of eeuuuwwww looks like here it is. Someone was apparently living here as there is a nice little nest and plenty of poop in brand of raccoon. Not too unusual to find vehicles like this. They are often stashed away in an old barn that has plenty of doggy doors for rodents, raccoons and god knows what else.

So I'm dragging it all back out. The axles are a bit rusty as the wheels have been removed from the gears. So I’m cleaning up the spindles a bit and putting on some grease so they will actually roll which is a nice feature at a time like this.

The surrey on the far right has been removed from it’s chassis. The chassis is laying on the lawn over on the left. I still have no idea if any wheels are going to fit. I manage to roll the surrey body out on a pair of wheels and an axle. Otherwise I have the trailer nearly empty but it’s pushing 2:00 and I need to get this stuff together, cleaned up a bit and put in a building.

There are four chassis and 16 wheels so I guess that’s a good sign. Let’s hope they all match.

So check back on Monday to see the results. I had a long day of loading, unloading, putting together, cleaning and putting away. I didn’t quite make it and the lawn looks like an auction will be held here tomorrow. But I did manage to get three vehicles under roof. This is really messy, dirty, hard work but some of my best memories of the carriage trade are rooting around in old barns. You never know what you will come across and today was a good day. See you on Monday.

Best!

Todd